Note: Names of organizations, offices, departments, etc. in the article are as of when the article was first published.

| Date | May 2019 |

|---|---|

| Place | Bacon Hut GRUN |

| Model in Use | TR-71wf |

| Purpose | Temperature monitoring to support consistent bacon quality |

The Hirugano Highlands, Gujo City, Gifu Prefecture, Japan.

On a fresh, clear day in May 2019, we visited a quiet highland area where mountain water naturally divides and flows toward two different seas. Just nearby stood a small, lodge-style building.

This is Bacon Hut GRUN, a small workshop where homemade bacon and ham are carefully crafted and sold.

The owner, Mizuhiko Yasuda, is affectionately known as “Hige-jii,” a nickname meaning “the bearded grandpa.” With his beard and gentle presence, he looks like someone who might have stepped out of a children’s story set in the Alps.

We came here to meet this bacon master.

“Welcome. Please, have a seat,” he said casually, guiding us to the porch.

A small table and LCD monitor had been set up there, and before we realized it, Mr. Yasuda pressed play. This, we learned, is GRUN’s style: first-time visitors are invited to taste the bacon, and while they wait, they are introduced to the workshop through a video.

It was there that we learned Mr. Yasuda had started Bacon Hut GRUN in 2011. Before that, he had spent more than forty years working at a long-established ham manufacturer. While he was there, working as part of a larger organization, he felt there were limits to how far he could pursue the kind of bacon he truly wanted to make.

So he left.

He chose Hirugano as the place to start over, building a small workshop where he could follow his own thinking, rely on his own senses, and take full responsibility for every step of the process. That decision became the foundation of Bacon Hut GRUN.

GRUN’s signature product is its additive-free, salt-only bacon. Just pork belly and salt. The pork belly is rubbed with salt, aged for more than two weeks, and then carefully smoked to draw out the meat’s full flavor.

Thin slices were placed on a pan and cooked simply, without oil or seasoning. A plate was set down quietly in front of us for tasting.

“Oh… wow,” we found ourselves saying almost at the same time.

The flavor was rich and deeply savory, yet surprisingly clean. It filled the mouth, then faded gently, leaving no heaviness behind. There was nothing to analyze, nothing to compare it to. It was simply good.

This first taste, we later realized, is the heart of GRUN. Many visitors come all the way to Hirugano just for this moment. Some even bring friends who are visiting for the first time — confident that a single bite is enough to convince them.

After that, lunch was served at the table.

Pasta and salad made with the same bacon were brought out. As we ate, Mr. Yasuda talked about what he had wanted to achieve from the very beginning.

He wanted to make bacon that was genuinely delicious, yet reasonably priced — and to show people just how good real bacon can be.

To do that, he explained, he sees himself as half craftsman, half researcher.

He trusts experience and intuition, but he also believes that maintaining high quality requires careful observation, verification, and consistency.

For him, understanding flavor also means making it repeatable — and that is where measurement naturally becomes part of the process.

As he spoke, Mr. Yasuda stood up and invited us into the workshop, saying he wanted to show us what that way of thinking looks like in practice.

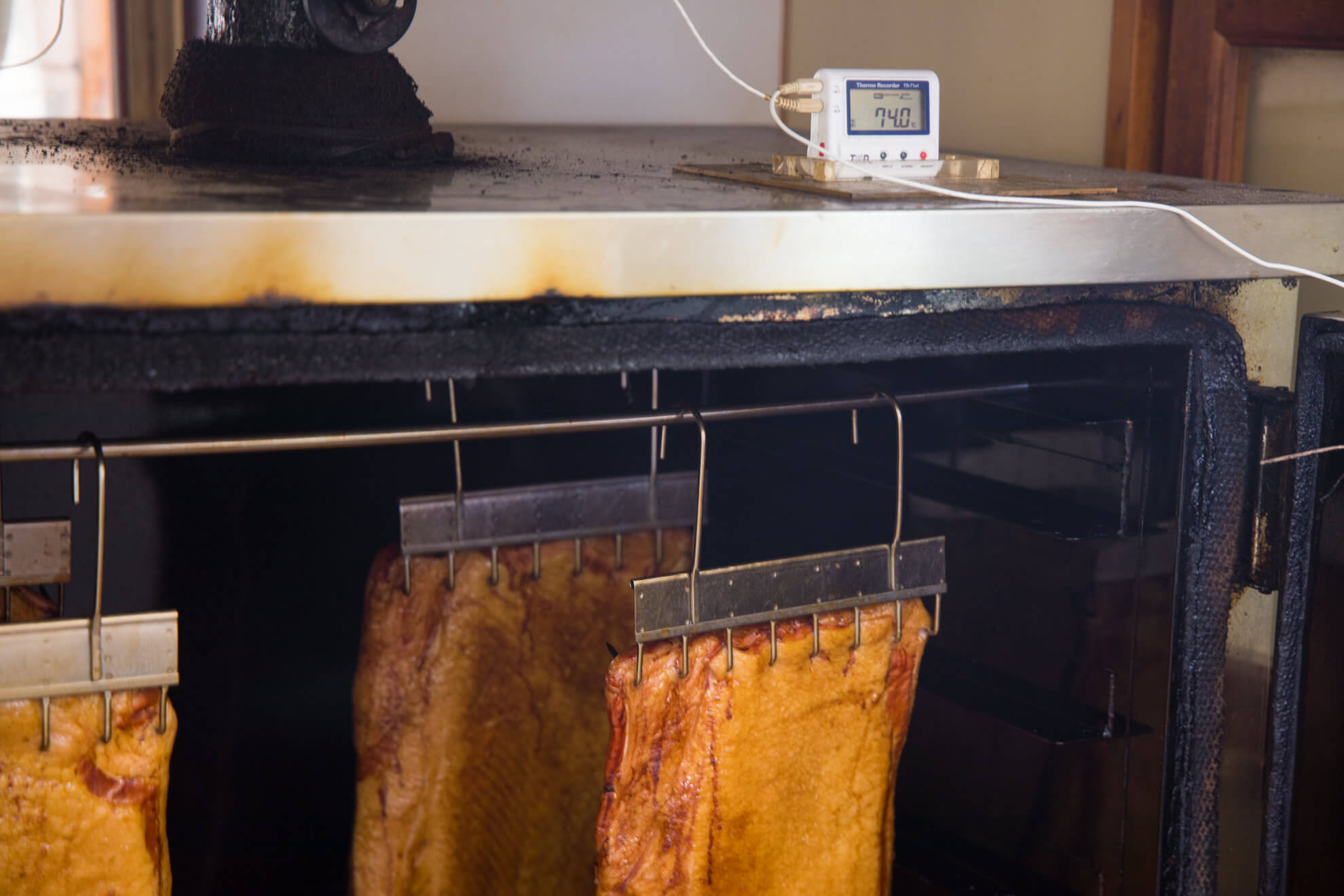

Inside the smokehouse, he showed us how the pork belly is repositioned during smoking to compensate for temperature variations and ensure even heat exposure.

To support this process, he uses a two-channel T&D data logger, the TR-71wf, which simultaneously measures and records both the internal temperature of the meat and the ambient temperature inside the smokehouse.

One of the two channels is connected to a TR-1220 sensor fitted with a stainless-steel protective probe, allowing him to track the temperature at the center of the meat as it smokes. The bacon is finished when the internal temperature reaches 70°C (158°F).

All recorded temperature data is stored and carefully reviewed. Rather than relying solely on experience and intuition, this steady process of data verification supports the consistent production of additive-free bacon, ensuring both safety and quality.

Before we left, we were offered a taste of the freshly finished bacon, still hot from the smokehouse.

“This doesn’t even feel like bacon anymore,” we said, half laughing — meant as the highest praise.

The flavor had gone beyond anything we thought bacon could be.

The taste was deeper and rounder than anything we had tried earlier, even compared to the bacon we had tasted before, almost overwhelming in its richness.

Before smoking, the pork belly is cured with a carefully calculated amount of salt — 1.5% of the meat’s weight — a ratio refined through years of testing and experience. Only salt is used.

After curing, the pork belly is vacuum-sealed and aged for more than two weeks at low temperature, a process designed to draw out the meat’s natural flavor without relying on additives. Throughout this critical aging stage, T&D data loggers quietly monitor temperature, ensuring a stable environment while allowing the bacon’s flavor to develop naturally.

This is where data plays its supporting role — not controlling the craft, but standing quietly behind it.

Later, back on the porch once again, we sat together and talked a little longer. As we prepared to leave, we found ourselves already wanting to come back.

What stayed with us wasn’t just the taste of the bacon, but the way craftsmanship, curiosity, and data coexist so naturally at GRUN.

Here, measurement doesn’t replace the maker’s senses. It supports them — quietly, reliably, and without getting in the way.

This is the kind of role T&D data loggers are meant to play: helping skilled makers preserve what matters most, while allowing their work to remain honest, consistent, and true.

Website:

http://www.gryun.com/

(Please note that Bacon Hut GRUN has since relocated to Fujimi Town, Nagano Prefecture.)